Stretching the Limits of VITA 48.2 Chassis Design

Most VPX systems make use of VITA 48.2 conduction cooled modules because of their established deployment track record. However, as module power continues to increase, VITA 48.2 struggles to dissipate the attendant heat using straight conduction cooling – leaving system designers with only two choices; move to VITA REDI alternatives or stick with VITA 48.2 and stretch the limits at the chassis level.

The choice is difficult because there are a variety of conflicting demands, including cost, module availability, chassis design, environment, size and weight. However, one thing is almost certain – whether at the chassis or module level, air or liquid cooling will play a role in that choice. Power hungry modules can leverage one of the thermally advanced VPX REDI standards, like VITA 48.4 liquid flow through (LFT) or VITA 48.8 air flow through (AFT), but when these modules are not yet readily available, the system designer will need to utilize hybrid cooling strategies using VITA 48.2 modules.

Given their performance record, broad supplier ecosystem and availability in a wide range of functions, the goal is to get the most out of VITA 48.2 modules. They use established chassis infrastructure and are far less expensive compared to VITA 48.4 /8 versions, which require precision machined conduction cooling frames supporting inlet and exhaust passages (VITA 48.8); and inlet /outlet quick disconnect mechanics (VITA 48.4) at each slot for heat removal, adding significant cost and complexity to the chassis. VITA 48.4 and 48.8 modules are not readily available in 6U or in 3U (48.4 does not address 3U). The scarcity of these modules makes system level cooling alternatives for that form factor even more important.

Hybrid Chassis Design

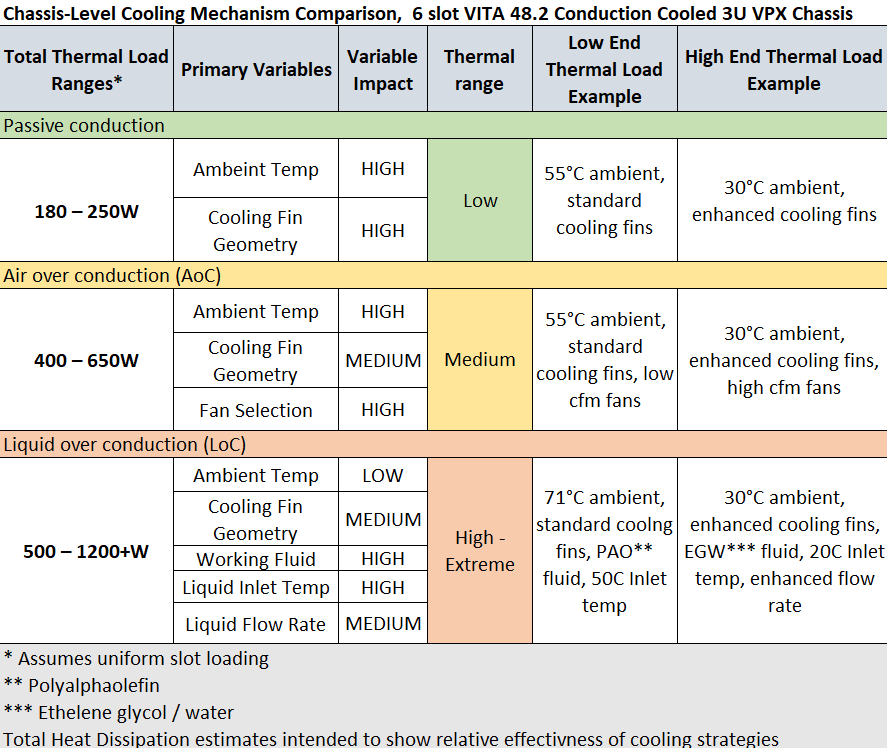

In 3U and 6U, extending the cooling capacity of VITA 48.2 chassis involves adding air or liquid assist to create hybrid designs that amplify the effect of the baseline conduction hardware. Thermal modeling and empirical data indicate that the cooling capacity in conduction only chassis can be increased substantially when applying air or liquid assist options. See table 1.

Table 1 (right) compares cooling capacity using passive, air assist and liquid assist conduction cooling in 6 slot VITA 48.2 3U VPX Chassis

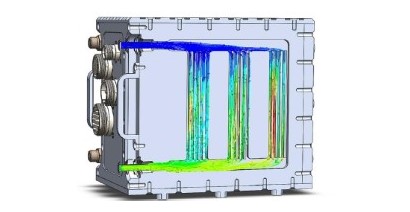

Air-over-Conduction Design

In a VITA 48.2 chassis, heat is conducted away from hot module components through the heat sink and out to the module wedge locks. Using air assist, an air-over-conduction cooled (AoC) VITA 48.2 chassis channels air through the chassis side walls perpendicular to the wedge locks. The chassis side walls contain cooling heatsinks and fans to supply adequate pressure and flow rate. The walled areas form enclosed air chambers isolated from the modules, envelope the payload section and concentrate air flow. Forced air runs co-planar to heatsink fins, drawing away excess heat. See figures 1.

Figures 1: air flow pattern in a conduction cooled chassis with air assist (left) and LCR AoC3U-410 air over conduction cooled VPX chassis (right)

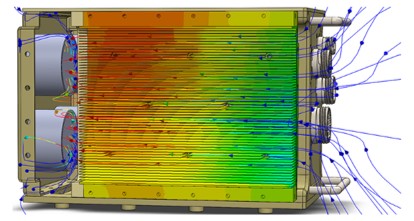

Liquid-over-Conduction Design

Liquid-over-conduction (LoC) VITA 48.2 chassis are used for high performance thermal requirements where air assist is insufficient, and where the application can support an external pump and chiller. LoC chassis channel the coolant perpendicular to the card edges through system cold plates (chassis side walls) similar to AoC chassis.

Two popular coolant choices are EGW (Ethelene glycol / water) and PGW (propylene glycol / water) mixtures where the glycol additive serves as an antifreeze. PAO (Polyalphaolefin), another coolant choice, sees popularity among military and aerospace applications primarily due to its dielectric properties. See figures 2.

Figures 2: liquid flow pattern in a conduction cooled chassis with liquid assist (left) and LCR LoC3U-510 liquid over conduction cooled ATR chassis (right)

For high speed VPX and SOSA aligned board payloads, precision engineered VITA 48.2 chassis cooling designs continue to offer solutions in high heat dissipating applications.

Learn more about our AoC and LoC chassis.

Leave a Reply

You must be logged in to post a comment.